MARCH MADNESS SALE

FREE SHIPPING ON ORDERS OVER $500

PLUS ADDITIONAL 10% OFF

Use Code: MADNESS

Excludes Coan, ATI, and Reid Products. Limited Time Only. Shipping discount automatically applied at checkout.

*One-way shipping only. Not valid for AK or HI.

68RFE CATEGORY 3 REBUILD KIT WITH TORQUE CONVERTER

Description

Kit Includes the Following:

- Sonnax Smart-Tech® Overdrive Clutch Housing Kit

- New 68RFE Thrust Washer Kit

- New 68RFE Thrust Bearing Kit

- 68RFE Complete Gasket and Sealing Kit

- 68RFE Spin-on Filter

- 68RFE Pan Filter

- 68RFE Thrust Bearing Kit

- Upgraded 2C Clutch Set

- 68RFE Billet 2C Piston

- 68RFE Accumulator Plate

- 4C Snap Ring Retainer

- Transgo 200 PSI Valve Body Kit (2007-2018 ONLY)

- Accumulator Piston Kit

- Zero Cavitation Filter Kit w/ MAG Pan

- 68RFE Low-Reverse Sprag

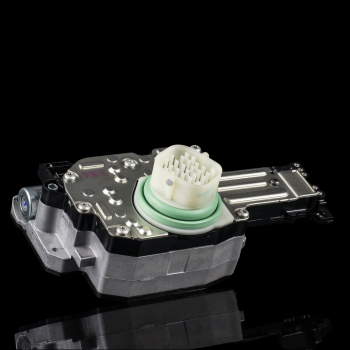

- Solenoid Pack

- Billet Valve Body Plate

- Billet Input Shaft

- Billet Flexplate

- 68RFE Billet 4C Reaction Ring Gear Thrust Washer

- 68RFE-46-3D Triple-Disc Torque Converter

In this new SunCoast Category 3 68RFE Rebuild Kit, we specifically add two changes versus the Category 2 68RFE Rebuild Kit: a Low/Reverse Sprag, Solenoid Pack, Billet Valve Body Plate, Billet Input Shaft, Billet Flexplate and a Triple-Disc Torque Converter with Billet Stator.

The 68RFE

The 68RFE transmission is the big brother to the 45/545RFE transmission. The RFE platform was originally designed by Chrysler and was introduced in 1999 with the debut of the new Jeep Grand Cherokee. The "RFE" stands for Rear-wheel drive Fully Electronic control. The RFE design was mostly noted in the new design to have 3 planetary sets for a 4-speed transmission in the 45RFE.

In 2007, Chrysler debuted the new 6.7 Powerplant in the all new Dodge Ram, and Dodge wanted a transmission that was specifically designed for function. The previous platform utilized the Torqueflite 48RE platform. The 46/47/48 Chrysler platforms were 3 and 4-speed units that were mechanically and hydraulically controlled, with the most notable control system being governor pressure.

The first improvement Chrysler wanted to make over the Torqueflite platform was, obviously, the amount of forward gears. For the 68RFE transmission, Chrysler opted to change to a six-speed unit. The additional gears allowed Chrysler to add higher 1st-gear ratios and tighter shift recovery from one gear to the next. The tighter shift recovery essentially keeps the vehicle in higher averaged horsepower and torque numbers, while also adding torque multiplication.

The gear ratios were increased. as well. The new 68RFE boasts a whopping 3.23:1 first gear, compared to the 2.45:1 first gear found in the previous 47/48RE platform. Chrysler also increased second gear to a 1.83:1 versus the 1.45:1 found previously. The 68RFE was also given two overdrive gears, with 5th being .81:1 and 6th with the very deep .62:1. The predecessor had a single overdrive that was a .69:1.

The Category Kits

The SunCoast Category 68RFE transmission rebuild kits are designed and developed with intentions of taking a systematic approach to solving the issues with the 68RFE transmission. We approach each deficiency and need with careful consideration.

These kits offer you the same recipes that are used in our facility when we build these units. We aim to offer you the most complete series of 68RFE rebuild kits available on the market today with proven combinations for a successful build.

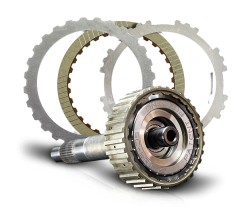

Dodge trucks pulling heavy loads or boosted to 500–600HP are at high risk for overdrive burnup due to the stock transmission’s insufficient clutch capacity and fragile OE clutches.

Even small amounts of heat and extra torque will push the thin (.034"), single-sided clutches over the edge, distorting the clutch pack. The fact is, any distortion of the clutch pack takes the clearance out of spec and makes overdrive clutch burnup inevitable.

Keep hardworking trucks on the road with the Sonnax Smart-Tech® overdrive clutch housing kit 72960-16K. The unique billet aluminum housing increases OD apply area by 16% and holds a physically taller clutch pack. The 2X thicker steels increase clutch pack steel mass by 28% for maximum heat dissipation. The double sided BorgWarner clutch frictions are optimized for the 68RFE OD application and custom-made for the Sonnax kit. This guarantees an unrivaled combination of squawk resistance and maximum clutch capacity for any truck.

This groundbreaking kit is the only top-of-the-line upgrade that eliminates clutch problems without relying on valve body/pump modifications or adding the expense of extra components.

- Modified housing holds physically taller clutch pack for 20% more clutch capacity

- 16% More OD apply area for firmer, more controlled shifts

- 2X Thicker steels and double-sided clutches increase steel mass by 28% for maximum heat dissipation

- Custom BorgWarner clutches for maximum capacity with state-of-the-art squawk resistance.

- Bolt-on anchor plate eliminates clutch pack flexing and distortion that contribute to heat build-up

- Combine with Sonnax line pressure booster kit RFE-LB1 for even higher levels of performance

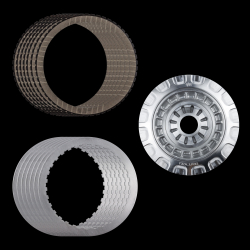

The 2C Piston

The factory molded piston is prone to uneven apply, which leads to excessive heat in the clutches and steels and creates premature failure. In this 68RFE transmission rebuild kit, we replace the factory piston with a much-improved billet piece that also allows for one additional clutch, further increasing surface apply area. This new billet apply pistons corrects these issues and adds matched performance

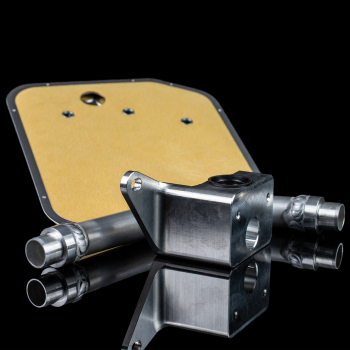

Zero Cavitation Filter Kit

The factory 68RFE has had many issues with pressure relief check valve system on the transmission pan filters. Initially Chrysler had issues with the plastic filter splitting in half. This was later remedied by adding a pressure relief valve on top of the filter. This later showed to be an issue as the valve would release itself from the filter altogether.

This new bottom feeder filter kit allows the usage of a torqueflite filter to not only prevent pump cavitation but allow higher volume of fluid to be passed through the system. This will also improve fluid flow in high line pressure situations.

The system requires either a deep aluminum Mag-Hytec that we modify or a specific OE pan. This kit comes with a specific OE pan.

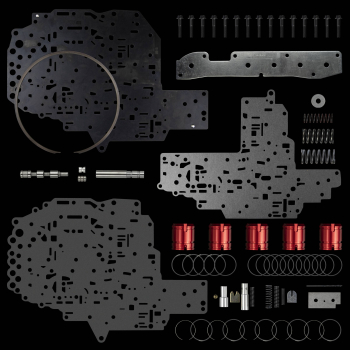

The High-Pressure Tuneless Reprogramming Kit

TransGo High-Pressure Tuneless™ Reprogramming Kits fit 1999 to 2018 Chrysler, Dodge, RAM, and Jeep vehicles equipped with 45RFE, 545RFE, 65RFE, 66RFE and 68RFE automatic transmissions equipped with gas or diesel engines. This kit provides increased transmission durability for engines with increased horsepower and torque output when aftermarket engine tuners and other modifications are installed.

Until now, when someone increased the power output of the engine, the only way to significantly increase the transmission operating pressure required reprogramming the computer. As a result, computer programming often leads to harsh or binding shifts, erratic operation, and at times, catastrophic internal hard parts failure.

Increasing main line pressure the conventional way with a pressure regulator spring could not be done because the computer monitoring system would recognize the higher-than-expected pressure and immediately set a code as well as putting the transmission into limp-in mode.

TransGo Tuneless technology provides a re-calibrated pressure curve that mirrors the throttle position and torque demand. Consequently, this elevated pressure curve delivers increased clutch and TCC holding capacity along with shorter cleaner shifts at all throttle openings. The patent-pending internally balanced calibrations provides a progressive clutch apply pressure that increases line pressure across the entire throttle span. As a result, max line pressure is now 210 psi which is a 30% increase over the OEM 160 psi max line! The Kit also addresses the converter clutch apply circuit with a built-in bypass to prevent converter ballooning that comes with elevated line pressure.

Features and Benefits:

- New pressure regulator spring and matching triple valve body separator plate that adds 30% more line pressure across the entire throttle curve to all of the clutch elements, therefore eliminating the need for computer programming

- New drop-in torque converter limit valve system for both early and late pumps, saving the cost of a new pump

- Converter clutch apply pressure bypass to prevent the torque converter from ballooning

- Replacement self-cleaning low/reverse switch valve as well as the end plug

- Optional TCC control valve for use with triple-disc converters for a smoother TCC apply

Corrects/Prevents/Reduces:

- Burnt OD frictions due to increased engine horsepower

- Rough lock-up

- TCC slide bang

- TCC slip codes

- Drain-back

- Limp-in mode

- Low line pressure and code P0868

Includes:

- Patent-pending triple valve body separator plate

- Valve body gaskets

- PR valve spring

- New drop-in torque converter limit valve system

- Drill jig, drill bit and deburring tool

- Heavy duty accumulator plate/cover

- Recalibrated OD accumulator springs and shim

- Replacement self-cleaning low/reverse switch valve as well as the end plug

- TransGo engineered accumulator seals

- TCC recalibration accumulator springs and retainer

- Heavy duty snap ring for input drum

- Optional TCC control valve for use with triple-disc converter

The Piston Replacement

Accumulator piston scuffing and bore wear are common issues in Chrysler 45RFE, 545RFE, 65RFE, 66RFE and 68RFE valve bodies, especially when running increased pressures. The OE accumulator pistons have two seal rings. The seal groove at the open end of the piston is a larger diameter, with the seal ring acting as a guide to prevent piston-to-bore contact. The seal groove at the closed end of the piston is a smaller diameter, and the seal ring acts as a conventional seal. However, due to the smaller seal groove diameter, the piston will contact the bore when side-loaded, resulting in scuffing, wear and leakage of clutch apply pressure.

Sonnax Accumulator Piston Kit (44894-01K) features two guide seal rings, one at each end of the piston to prevent piston-to-bore scuffing when side loaded. Additionally, the oil sealing ring location is relocated on the piston, allowing it to run in an un-worn portion of the bore and enabling bores with moderate scuffing to be salvaged. Manufactured from 6061 billet aluminum, these pistons will upgrade late-model applications with plastic pistons to prevent transmission failure due to piston breakage.

- Dual-guide seals prevent piston-to-bore scuffing

- Updated seal location allows use in scuffed bores

- Prevents transmission failure from broken plastic pistons

The Deep Pan

What is the easiest upgrade to ensure long service life out of your 68RFE transmission? A simple pan upgrade does wonders. In this kit, you will receive a Mag-Hytec deep aluminum pan. This new 68RFE deep aluminum pan will add an additional 4 quarts of transmission fluid. The additional fluid will increase surface area for the fluid, ensuring cool temperatures when towing or hauling. This new deep 68RFE pan also is equipped with a flush mount drain port, allowing quick and easy fluid replacement. This pan is ribbed, allowing for additional heat dissipation and structural integrity to keep flex at a minimum.

This pan is also modified specifically to fit the Suncoast Zero Cavitation filter kit.

The Torque Converter

The Category 1 SunCoast Torque Converter for 68RFE transmissions is engineered to handle all of your every-day duties. Whether you're towing a camper or hauling dirt to a job site, this torque converter is designed to improve vehicle response and give you years of solid, reliable performance. It comes with furnace-brazed fins and hardened turbine splines. The clutches in this converter are carbon-graphitic for precise and accurate lock-up.

The front cover is CNC'd from 4140 HTSR steel to exact tolerances. The factory apply piston on these units is known to be a weak link on the 68RFE torque converters. On the SunCoast Category 1 68RFE Torque Converter, the apply piston is also upgraded to billet material, ensuring zero deflection when applied and precise-lock up consistently for the life of the vehicle.

If you are looking to increase the performance of the factory unit and looking for a cost-effective solution, this is the converter for you.

The Flex Plate

The SunCoast 68RFE-BFP Billet Flex Plate for your 2007.5 - 2018 Dodge 6.7L Cummins is a must-have when it comes to putting power to the ground in your truck. The high torque of your Cummins, in conjunction with a better-designed torque converter, can transfer the torque with no slip. The flex plate is bolted to the crank shaft, then the converter is bolted to flex plate. The torque from your Cummins is transferred to the flex plate, from the flex plate to the torque converter then to your input shaft in the trans. With increased torque from the engine and no slip out of the converter, it can crack and/or rip the center out of a stock flex plate.

The SunCoast billet flex plates are CNC-machined from a forging for strength, and reliefs are machined out between the converter mounting area and the crank flange to enable some flex. We designed our flexible billet flywheel with the understanding that it needs to flex, but at the same time, we added extra thickness to prevent cracking. We started with a better quality material and a better manufacturing process to make it stronger. Our flexible flywheel made or exceeded all the SFI specification 29.3 requirements for materials, mechanical properties, design and rotational integrity.

NOTE: An SFI-certified flywheel flex plate is required on drag racing vehicles running 11.99 and quicker in the 1/4 mile and 7.49 and quicker in the 1/8 mile, or any vehicle exceeding 135mph. It was changed in 2008 from the 29.1 SFI specification to the SFI specification 29.3 for automatic transmission flex plates for diesel applications.

The new rules for the flexplate require that the material can not be a stamped metal, as many OEM and aftermarket flex plates are. To maintain the SFI specification 29.3 requirements, the flex plate must be replaced every three years.

The Input Shaft

Probably the first hard part to fail on the 68RFE is the input shaft. When you add larger wheels and tires and a few minor upgrades, this problem becomes even more likely to develop. This input shaft is a drop-in replacement part for high power/torque applications and is made from billet 300 Maraging (VASCOMAX) steel alloy for high yield strength. The shaft is also heat-treated and precision-ground. The shaft then is gun drilled through hole to eliminate stress risers often associated with conventional drilling procedures.

These new 68RFE transmission rebuild kits are designed with the builder in mind, and we offer from mild to wild depending on what your needs are.

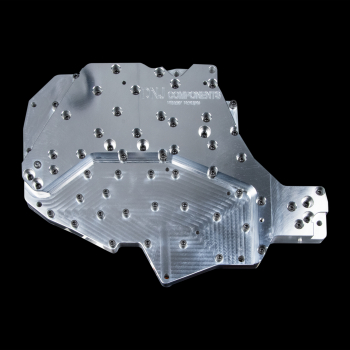

The Billet Valve Body Plate

Since its early production in 1999, the RFE platform has been plagued with many issues. Some of the biggest problems have been premature clutch failure and valve body wear. The premature clutch failure can be isolated to hydraulic cross leaks and warped valve bodies. Approximately 80-90% of those cross leaks have been found in the OE channel plate casting. If you look closely at the stock casting with a straight edge, you will notice there is some severe flexing and warpage. Looking at how the valve body is fastened to the transmission, and being that there are limited contact surfaces, it's no wonder we see so many problems (for example: 4th-gear clutch failure, premature valve body bores worn, and defective valve lands).

It has been noticed over the years that in many cases the same vehicle would require another new valve body after only 60-70,000 miles. So, it was decided that the best way to fix this issue was to eliminate channel plate flexing.

DNJ developed a new plate made of billet aluminum that has shallow hydraulic circuits and is made from a solid 1" piece of material, machining away only what is necessary to ensure no war-page and a very solid foundation to bolt the valve body back to. Also, we have slightly moved some passages and eliminated those not necessary in hopes of stopping separator plate chafing and valve body breakage and cracking from high line pressure in performance applications.

With our the billet channel plate, the end user is able to use the stock hardware. They can also choose whether they want to use a bonded separator plate or a good used stock one. DNJ has done extensive testing to their plate to ensure zero warpage. For an understanding of the durability, we tested the strength of the plate. We put the stock plate on a press that has a pressure gauge. With the edges supported just like factory, we then put a 1.000-inch round bar in the center. At 300 lbs of pressure the stock plate warped to .168 and then cracked. We then did the same to our plate. At 1 ton it did not move. We then went to 2 tons with barely any movement. Flex was .021. Then we went to 5 tons and it was .047. So, we decided that we would give it 10 tons. It flexed to .160, and out of fear we stopped. It didn't return to zero, but it did however recover to .056.

Details

- SC-68-3

- SC-68-3

- SC-68-3

- SunCoast Performance

- New

Categories

Shipping Information

- Item Requires Shipping

- 118.0 lbs.

- W33.5000” x H30.0000” x L29.5000”

- Free Shipping!

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

May We Suggest

Powered by Web Shop Manager.

WARNING: Cancer and Reproductive Harm

Write the First Review!