MARCH MADNESS SALE

FREE SHIPPING ON ORDERS OVER $500

PLUS ADDITIONAL 10% OFF

Use Code: MADNESS

Excludes Coan, ATI, and Reid Products. Limited Time Only. Shipping discount automatically applied at checkout.

*One-way shipping only. Not valid for AK or HI.

CATEGORY 4 SUNCOAST 950+ HP CUSTOM ALLISON REBUILD KIT - NO CONVERTER

Description

950+ HORSEPOWER LB7/LLY 5-SPEED CATEGORY 4 SUNCOAST REBUILD KIT

Kit contains the following:

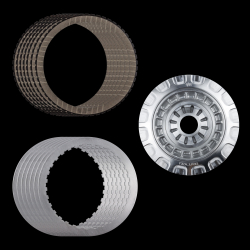

- SunCoast custom clutch packs

- SunCoast custom Steels

- SunCoast custom billet plates

- SunCoast custom overhaul kit

- Valve body calibration kit

- SunCoast gasket kit

- Pan Filter

- Spin on filter

- Pan gasket

- SunCoast Filter Loc

- New internal wiring harness

- Billet SFI certified Flexplate

- Billet Input Shaft

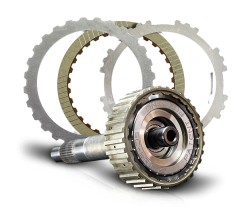

- Billet P2 planet assembly

- Billet C2 clutch hub

- Billet Intermediate Shaft

- Billet Output Shaft

- Modified Sun Gear

The SunCoast Category transmissions utilize the latest proven friction materials and steel technology from industry leading companies such as Alto and Raybestos. SunCoast works directly with these companies to design and manufacture proprietary SunCoast exclusive product lines, giving the end user uncompromised quality throughout the entire transmission.

SunCoast has designed these kits in house to exact specifications for many in tents, including but not limited to towing, sled pulling, racing or simply having a vehicle to get from point A to point B.

Designed for light commercial vehicles in both on highway and public transport applications, Allison Transmission's 1000 and 2000 Series are rated up to 400 horsepower from the factory. Allison 5-speed transmission started in 2001 with GM equipped Duramax engines.

Transmission Exclusives:

- - SunCoast proprietary C1, C2, C3, and C4 Alto carbonite frictions/Rabestos SCZ frictions that contain no center slots. These frictions utilize a waffle pattern in the material to help retain oil helping the clutch cool when not applied.

- - Redesigned apply pistons with improved rubber compounds proven to hold higher heat. This custom piston allows us to use a thicker spring apply plate which replaces the thin OEM one that will cone and cause uneven apply surface resulting in premature clutch failure.

- - Custom SunCoast apply plate that redirects fluid to better lubricate frictions from the inside out which lubes the entire friction rather than OEM style that lubricates from the center out leaving the inner half of the clutch burnt.

- - Includes exclusive smart trim / clutch control valve.

- - Includes all items needed to modify the C2 clutch piston for increased clutch durability.

The Flexplate

This SunCoast Allison billet SFI certified billet flexplate replaces the factory flex plate with an improved billet steel one piece design. This eliminates the weak factory flex plate. This replacement Allsion flex plate is a must with the high torque in conjunction with a better designed torque converter that can transfer torque with no slip. The felxplate is bolted to the crankshaft and then the torque converter to the flex plate. This one piece billet flex plate is SFI certified to 29.3.

Note: A SFI certified flexplate is required on drag racing vehicles running 11.99 and quicker the 1/4 mile and 7.49 and quicker in the 1/8 mile, or any vehicle exceeding 135mph. In 2008 it was changed from the 29.1 SFI specification to the 29.3 specification for automatic transmissions for diesel applications. The new rules for the flex plate require that the material cannot be stamped metal as are many OEM flex plates.

The Input Shaft

The input shaft is the first thing to go south with the Allison transmission. This Allison billet input shaft is built to withstand everything you can throw at it. This new Allison billet input shaft is manufactured from 9310 Vacumelt steel which increases torsional fatigue strength by over 50%. The SunCoast Allison billet input shaft is machined with a larger radius at the turbine spline for added strength. This a must for vehicles that are lifted with larger wheels and tires, for heavy towing and hauling, and vehicles with aftermarket turbos.

Billet Intermediate shaft

The factory intermediate shaft is one of the last hard parts to break typically on the Allison transmission. SunCoast replaces this shaft on transmission that will be exposed to power levels above 750 horsepower. This new Allison billet intermediate shaft is made from a much stronger 300M billet material. This new billet intermediate shaft also feature an exclusive additional lubrication hole for the P3 sun gear and pilot increasing the life of that circuit. This SunCoast Allison intermediate shaft also has been gun drilled to provide a polished interior finish to eliminate any internal stress risers. This shaft is also heat treated for added strength and reliability.

Billet Output Shaft

The Allison output shaft can be subjected to a tremendous amount of torsional fatigue. This issue can be even more troublesome with heavy towing/hauling or when increasing horsepower and torque. SunCoast replaces the factory Allison output shaft with a billet piece on our Category 4 Allison rebuilds. This new Allison billet output shaft is machined from 300M billet steel and is a direct drop in replacement.

New internal wiring harness

Every build here at SunCoast reliability is our number one priority. Each one of our (Category) Allison rebuild kits comes with a new internal wiring harness. As the transmission continues to age, the plastic connectors become brittle and will break during disassembly. This often leaves builders scrambling around looking for a replacement last minute. This is a new GM harness with all new connectors.

The Billet C2 Clutch Hub

The Allison transmission is an incredibly robust unit, however when exposed to conditions outside what it was designed for weak points begin to expose themselves. The factory C2 clutch hub has been known fail prematurely. This issue is most commonly seen in conditions where larger tire/wheel combinations, heavy towing/hauling, sled pulling, drag racing, and larger shock loads.

SunCoast replaces the factory C2 clutch hub with a much stronger billet piece that is manufactured from 4140 heat treated stress relieved steel. This new Allison billet C2 clutch hub has had the spline lengthened .125 for increased contact area. The spline boss diameter has also been increased .100 for added strength. This Allison billet C2 clutch hub is installed on all SunCoast 700 horsepower category 3 transmissions.

The Billet P2 Planet

The P2 planet with the Allison transmission can strip or snap as a result of poor tuning, shock load, improperly built transmissions and higher horsepower applications. This failure can and will result in catastrophic failure and ore immobility. The SunCoast P2 planet is the solution to the issue. This item is manufactured here at SunCoast using 4140 billet steel that is then induction hardened. This item is highly recommended for higher horsepower applications, including sled pulling, drag racing, as well as heavy duty towing. This planet comes with a machine SunGear which is required for use of the planetary.

This replaces the factory flywheel/flex plate with a improved bil- let steel one piece design and eliminates the heavy cast iron and the weak stamped steel flex plate. This is a must with the high torque in conjunction with a better designed torque converter that can transfer the torque with no slip. The flex plate is bolted to the crankshaft and then the converter is bolted to flex plate. The torque from the motor is transferred to the flex plate, then goes from the flex plate to the torque converter and finally to the in- put shaft in the transmission. With increased torque from the engine, it can crack and/or rip the center out of a stock flex plate. NOTE: A SFI certified flywheel flex plate is re- quired on drag racing vehicles running 11.99 and quicker in the 1/4 mile and 7.49 and quicker in the 1/8 mile, or any vehicle exceeding 135 mph. It was changed in 2008 from the 29.1 SFI specification to the SFI specification 29.3 for automatic transmission flex plates for diesel applications. The new rules for the flex plate requires that the material cannot be a stamped metal as are many OEM and after market flex plates. To maintain the SFI specification 29.3 requirements, the flex plate must be replaced every three years. Built to withstand everything thrown at it. Made from a select grade of super strength steel. Shaft is 50% stronger than the O.E.M. shaft. Made from 9310 Vacumelt steel. Precision ground for high dimensional accuracy. Ideal for heavy duty service applications. Input shaft is machined with larger than O.E.M. radius at turbine spline for added strength. P2 heat treated Plane tary fix kit Contains (1) Machined P2 Planetary. The stock Allison 1000 P2 Planetary can strip or snap as a result of poor tuning,shock load, improperly built transmissions and higher horsepower applications and can cause catastrophic failure and/or immobility. The SunCoast P2 Planetary fix is the solution to this issue. This item is highly recommended for higher horsepower applications, including sled pulling, drag racing, as well as heavy duty towing (to accept billet P2 hub, machine work required on the P1 sun gear). 4140 Billet steel Induction heat treated This does not include a C2 clutch hub

Planetary core deposit ($950.00) is required if pre-shipped (planet must be build able to receive core deposit back)

Details

- GMAX-CAT4-LB7/LLY-KIT-LC

- GMAX-CAT4-LB7/LLY-KIT-LC

- SunCoast Performance

- New

Categories

Shipping Information

- Item Requires Shipping

- 87.0 lbs.

- W35.5000” x H32.0000” x L23.0000”

- Free Shipping!

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

May We Suggest

Powered by Web Shop Manager.

WARNING: Cancer and Reproductive Harm

Write the First Review!