MARCH MADNESS SALE

FREE SHIPPING ON ORDERS OVER $500

PLUS ADDITIONAL 10% OFF

Use Code: MADNESS

Excludes Coan, ATI, and Reid Products. Limited Time Only. Shipping discount automatically applied at checkout.

*One-way shipping only. Not valid for AK or HI.

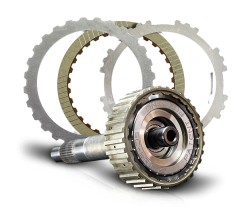

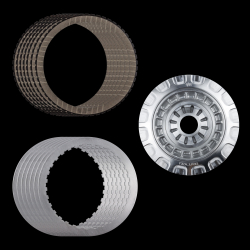

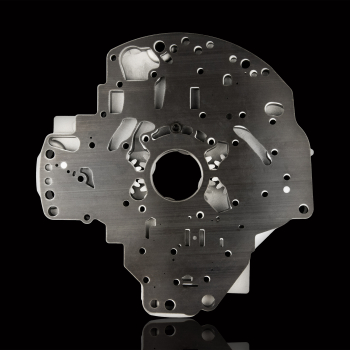

68RFE Pump Half (With Gears and Plate) 2007.5-2018

New

N72510C

68RFE Pump Half With Gears and Plate 2007.5-2018

USD

517.00

Pricing:

$517.00

Details

- N72510C

- N72510C

- SunCoast Performance

- 2018 Dodge 2500

- 2018 Dodge 3500

- 2018 Dodge Ram 2500

- 2018 Dodge Ram 3500

- 2018 Dodge Ram 2500 Van

- 2018 Dodge Ram 3500 Van

- 2017 Dodge 2500

- 2017 Dodge 3500

- 2017 Dodge Ram 2500

- 2017 Dodge Ram 3500

- 2017 Dodge Ram 2500 Van

- 2017 Dodge Ram 3500 Van

- 2016 Dodge 2500

- 2016 Dodge 3500

- 2016 Dodge Ram 2500

- 2016 Dodge Ram 3500

- 2016 Dodge Ram 2500 Van

- 2016 Dodge Ram 3500 Van

- 2015 Dodge 2500

- 2015 Dodge 3500

- 2015 Dodge Ram 2500

- 2015 Dodge Ram 3500

- 2015 Dodge Ram 2500 Van

- 2015 Dodge Ram 3500 Van

- 2014 Dodge 2500

- 2014 Dodge 3500

- 2014 Dodge Ram 2500

- 2014 Dodge Ram 3500

- 2014 Dodge Ram 2500 Van

- 2014 Dodge Ram 3500 Van

- 2013 Dodge 2500

- 2013 Dodge 3500

- 2013 Dodge Ram 2500

- 2013 Dodge Ram 3500

- 2013 Dodge Ram 2500 Van

- 2013 Dodge Ram 3500 Van

- 2012 Dodge 2500

- 2012 Dodge 3500

- 2012 Dodge Ram 2500

- 2012 Dodge Ram 3500

- 2012 Dodge Ram 2500 Van

- 2012 Dodge Ram 3500 Van

- 2011 Dodge 2500

- 2011 Dodge 3500

- 2011 Dodge Ram 2500

- 2011 Dodge Ram 3500

- 2011 Dodge Ram 2500 Van

- 2011 Dodge Ram 3500 Van

- 2010 Dodge 2500

- 2010 Dodge 3500

- 2010 Dodge Ram 2500

- 2010 Dodge Ram 3500

- 2010 Dodge Ram 2500 Van

- 2010 Dodge Ram 3500 Van

- 2009 Dodge 2500

- 2009 Dodge 3500

- 2009 Dodge Ram 2500

- 2009 Dodge Ram 3500

- 2009 Dodge Ram 2500 Van

- 2009 Dodge Ram 3500 Van

- 2008 Dodge 2500

- 2008 Dodge 3500

- 2008 Dodge Ram 2500

- 2008 Dodge Ram 3500

- 2008 Dodge Ram 2500 Van

- 2008 Dodge Ram 3500 Van

- 2007 Dodge 2500

- 2007 Dodge 3500

- 2007 Dodge Ram 2500 Van

- 2007 Dodge Ram 3500 Van

- New

Categories

- Parts - DODGE CUMMINS - 68RFE

- DODGE CUMMINS - 68RFE - Valve Body

- DIESEL - Diesel Products

- 68RFE|Valve Body|Diesel Products

Shipping Information

- Item Requires Shipping

- 5.0 lbs.

- W10.0000” x H10.0000” x L6.0000”

- Free Shipping!

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

May We Suggest

Copyright © 2026 SunCoast Diesel. All Rights Reserved.

Powered by Web Shop Manager.

Powered by Web Shop Manager.

Write the First Review!