MARCH MADNESS SALE

FREE SHIPPING ON ORDERS OVER $500

PLUS ADDITIONAL 10% OFF

Use Code: MADNESS

Excludes Coan, ATI, and Reid Products. Limited Time Only. Shipping discount automatically applied at checkout.

*One-way shipping only. Not valid for AK or HI.

SUNCOAST ALTO 4L80/85E CATEGORY 5 REBUILD KIT

Description

Features and Benefits:

- NEW 4L80E OVERHAUL KIT

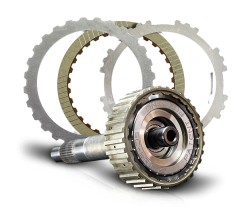

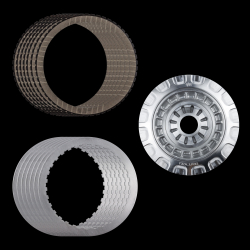

- ALTO RED EAGLE CLUTCH PACKS WITH INCREASED CLUTCH COUNT

- HIGH PERFORMANCE KOLENE STEELS

- UPGRADED INTERMEDIATE BAND

- NEW 4L80E FILTER

- NEW 4L80E BUSHING KIT

- NEW 4L80E THRUST WASHER KIT

- NEW LOW/REVERSE ROLLER CLUTCH

- UPGRADED 34 ELEMENT SPRAG

- UPGRADED SEPARATOR PLATE

- UPGRADED STATOR SUPPORT BUSHING

- TORLON CHECK BALLS (10)

- UPGRADED CASE SUPPORT BUSHING

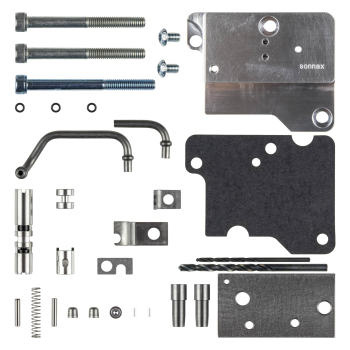

- TRANSGO STAGE 2 SHIFT CALIBRATION KIT

- SONNAX SMART TECH OVERUN KIT

- EXTREME DUTY FORWARD CLUTCH HUB

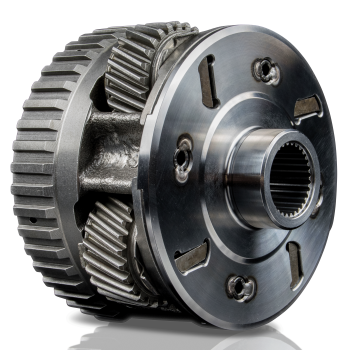

- UPGRADED BILLET OVERDRIVE PLANET

- 300 MARAGING BILLET INPUT SHAFT

- AEROMET MAIN SHAFT

- TRIPLE DISC BILLET 258MM TORQUE CONVERTER

In this Category 5 4L80E Rebuild Kit, one key upgrade when comparing it to the Category 4 4L80E Rebuild Kit is the input shaft. It is upgraded from 300M to a 300 Maraging billet material.

The 4L80/85E Transmission

The 4L80E (and similar 4L85E) was a series of heavy-duty transmission assemblies from GM designed for rear wheel drive configurations. The 4L80E was heavily based on the TH400 first produced in October 1963, adding electronic controls and an overdriven fourth gear. The 4L80E's were optioned only in Chevrolet/GMC pickups, 2500 Suburbans, vans, and commercial vehicles, and the Hummer H1. The 4L80E proved to be a big hit in 1991 with its release in the Silverado 454SS.

The 4L80E (RPO MT1) is rated to handle engines with up to 440 ft lb while the big brother the 4L85E (RPO MN8) is rated to handle vehicles with up to 690 ft lb.

This is a complete 4L80E super rebuild kit containing Alto Red Eagle clutches with upgraded power clutch pack that includes additional clutches and steels. The additional friction count along with the upgraded steels will improve your 4L80E's torque and horsepower capacity.

This kit will include everything else you need to rebuild your 4L80E transmission. A new filter is included as well as a bushing kit and and thrust washer kit. The band in the kit is a high performance RedEagle band.

Supporting the stator

In this SunCoast GM 4L80E transmission rebuild kit we include an upgraded Sonnax stator support bushing.

GM 4L80E and 4L85E units may display no converter lockup or codes 68, 39, 1870 or P0741. Imbalance of torque converter clutch apply oil through the front stator support bushing contributes to this complaint. A journal clearance of .002" or more will generate sufficient leakage to cause lockup clutch slippage, causing the transmission to stay in third gear. Sonnax front stator support bushing 34016-W is designed to reduce leakage by minimizing journal clearance and also increasing journal length.

Sealing Things Up

SunCoast always upgrades the check balls in all of our new 4L80E and 4L85E transmission rebuilds. In this kit you will receive 10 of these new Torlon check balls.

These new checkballs (.250") are made out of tough, wear-resistant imidized plastic. The imidized plastic balls seal better than steel balls because they conform to the separator plate ball seats. Steel checkballs are hard and heavy, wearing separator plate ball seats from the repeated high impact of the ball on the seat. Elastomer or rubber check balls seal well. However, the elastomer material wears, reducing the size of the ball. Similar imidized plastic balls have been used on some original equipment late model valve bodies with excellent results. These imidized plastic checkballs are not available through the original manufacturer.

Upgraded sprag

The intermediate sprag on the 4L80E's typically come with a 16 element intermediate sprag assembly. The can lead to failure in high horsepower and torque situations. In this 4L80E transmission rebuild kit we are upgrading the sprag to a 34 element sprag doubling the torque capacity.

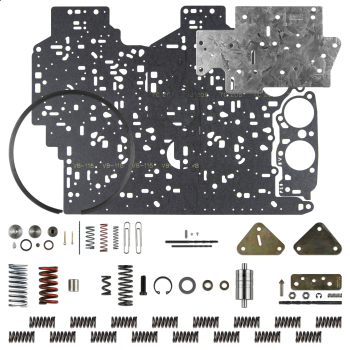

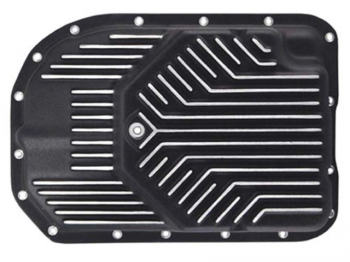

A Different Plate to Serve On

On many 4L80/85E rebuilds it is not uncommon to find the factory separator plate damaged beyond repair. This is a direct result of the factory steel check balls beating the plate repeatedly.

This SunCoast 4L80E rebuild kit also has a new upgraded separator plate included with it. We use a Transgo tempered steel separator plate for longer life. This plate is custom-plated for rust resistance.

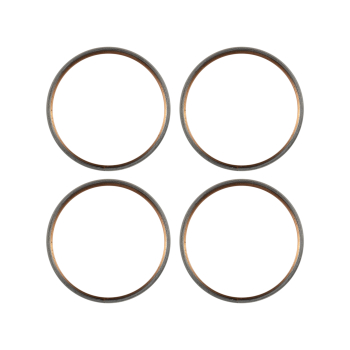

Upgraded Case Bushing

If you rebuild a lot of 4L80E's then you already know that case bushing walkout and thrust washer wear are common issues in the GM 400, 4L80E and 4L85E units. This upgraded heavy duty case bushing kit combines the tried and true no-walk case bushing with a high quality thrust bearing that replaces the OE thrust washer and selective spacer to update this area for maximum durability in all applications. Selective shims are included for setting and adjusting rear end play.

When in Doubt, Ask for Help

Insufficient holding power in the overdrive roller clutch is the underlying cause of chronic overdrive roller clutch failure in hardworking 4L80E and 4L85E transmissions. When the roller clutch fails, the damage can be catastrophic, and the only fix is replacing the drum, planetary assembly and mating components.

The Sonnax Smart-Tech Overrun Clutch Valve Kit (34200-40K) offers a hydraulic solution to this known mechanical problem. With unique rerouting of hydraulic fluid pressure, this patented kit keeps the overrun clutch applied at all times (except OD 4th), reinforcing the roller clutch to adequately support heavy loads.

- Improves OD roller clutch holding power in D4 and Reverse ranges

- Extends the life of workhorse transmissions while preventing warranty claims and comebacks

- Installs quickly onto the valve body — no transmission removal needed

The Extreme Forward Clutch Hub

Sonnax Extreme Duty Forward Clutch Hub Kit (34322-02K) is manufactured from forged 4140 steel and features nitrited and case-hardened splines to eliminate spline wear in extreme applications. Includes bearing between hub and direct clutch housing. The case-hardening at bearing surfaces is removed to make further modifications easier. This forward clutch hub and bearing combination shifts the support of the forward clutch hub from the main shaft to the direct housing and sun gear shaft.

Compared to OE or other replacement forward clutch hubs, Sonnax Extreme Duty Forward Clutch Hub Kit (34322-02K) has an additional .025” thickness designed-in to reduce endplay and provide further endplay adjustment options. No machining is required for typical installation.

- Eliminates spline wear in extreme power and offroad applications

- Simple installation adds bearing and reduces unit endplay

- Easily modified for addition of second bearing

The Forward Clutch Hub

This 4L80E rebuild kit also comes with a new heavy duty forward clutch hub. This is an ideal upgrade over OE hubs in GM 400, 425, 4L80E and 4L85E applications that commonly see a high fracture rate of the forward clutch hub. It is made from 1045 steel forging and features a thicker cross section for increased strength and rigidity that is so commonly seen in these units.

- Made from forged 1045 steel

- Thicker cross section for increased strength

- Added durability for daily drivers, work trucks and mild performance applications

Upgrading the Input Shaft

The 4L80E, while inherently strong, still has limits. When we are talking about limits, we are faced with the realization that the factory cast input can and will break. This can be to either shock load causing a sheer break or due to torsional fatigue, causing a fatigue break.

In this SunCoast 4L80E Rebuild Kit, we upgrade the input shaft to a billet one. This new billet 4L80E input shaft is manufactured from 300 Maraging billet steel. This shaft is vastly stronger than the OEM shaft and is a must-have component for higher horsepower and heavy towing applications.

Upgrading the mainshaft

Main shaft failure is a common problem in extreme duty GM 400, 4L80E and 4L85E units. OE and aftermarket shafts simply don't hold up in extreme horsepower applications, leading to spline twist and shaft breakage. This upgraded billet extreme duty main shaft is manufactured from an exceptionally tough high-strength Aeromet steel alloy with proprietary heat treatment for unrivaled performance and durability. An advanced torsional design with spline and cross hole refinements make this the most durable 1" main shaft available. This shaft withstood extensive track and lab testing with unbroken results in the most extreme applications. Recommended for applications above 1,000HP. Top-notch engineering and precision manufacturing deliver unrivaled performance and durability in the 1” stock size.

- Rear spline prevents the rear internal gear journal-end from twisting off by engaging the full internal spline of the gear

- Extensive in-vehicle and lab testing with unbroken performance

Can be used to replace late 4L80E and 4L85E solid shafts, however, check clearance between front of main shaft and rear of input shaft. It may be necessary to remove approximately .060" from front of main shaft or rear of input shaft.

The Shift Calibration Kit

This SunCoast 4L80E Rebuild Kit would not be complete without a shift calibration kit for the valve body. SunCoast likes to use a Transgo HD-2 Shift Calibration Kit in these units. This kit includes the following:

- New boost valve assembly

- High pressure relief assembly

- Stronger, better designed solenoid filter

- Case to center support seals

- 4th clutch strong bolt and other items which improve overall driveability and durability

- Upgraded triple layer separator plate with dual feed direct clutch

- Thicker intermediate snap ring

- Direct clutch high rate springs

This Transgo kit also features the following:

- Tuneable shift feel options

- Easy install, superb for heavy duty trucks

- Holds BIG horsepower

This kit also corrects and alleviates the following issues:

- High pressure parts breakage

- Direct clutch burn up

- Soft 2-3

- Slide-bang 1-2

- Low pressure due to solenoid filter breakup

- Missing shifts with no diagnostic codes

- Codes: P0731, P0732, P0733, P0734, P0751, P0756, P0894, P1870

Upgraded Torque Converter

This SunCoast Category 5 4L80E transmission rebuild kit also comes complete with an upgraded triple disc billet torque converter that is available in a variety of stall speeds. This is our Pro-Loc series of SunCoast triple-disc billet torque converters.

These have a host of internal upgrades:

- Chromoly steel turbine and impeller hubs for added strength

- Fully-machined forged front billet cover

- Damperless CNC'd billet apply piston add strength and durability

- Sprag cartridge delivers more than twice the holding capacity of OE

- Weld-on pilot adapts to many applications

- Furnace-brazed and tig-welded fins

- Carbon-graphitic clutch material ensuring precise lock-up control

- Custom-modified stator assembly

This torque converter, while capable of handling the added demands of high performance vehicles, also maintains the refinement and functionality to be used in a daily driven heavy duty application such as towing. This converter can be used as a stock replacement and requires no modifications to your transmission.

The Friction Material Test

Alto Red Eagle® material offers similar mid-point coefficient at high horsepower applications. In addition, the Alto Red Eagle® material gives superior friction wear characteristics at high energy engagements. The leading competitor's material degrades thermally and physically after reaching approximately 2.25 HP/in2.

Below we offer some engineering data collected with this particular clutch.

Six Level High Energy Test

On Frictional Properties And Wear

Lbs./Sq. Inch Pressure Required To Stop Flywheel In One Second

| Levels | Cycles | OEM Manufacturer A Pressure Required (Lbs./Sq.In.) |

OEM Manufacturer B Pressure Required (Lbs./Sq.In.) |

ALTO Red Eagle Pressure Required (Lbs./Sq. In.) |

| 1 | 10 | 64 | 70 | 66 |

| 1 | 100 | 65 | 71 | 65 |

| 2 | 10 | 72 | 84 | 74 |

| 2 | 100 | 73 | 84 | 74 |

| 3 | 10 | 85 | 96 | 86 |

| 3 | 100 | 92 | 101 | 93 |

| 4 | 10 | 102 | 116 | 104 |

| 4 | 100 | 110 | 122 | 108 |

| 5 | 10 | 118 | 133 | 117 |

| 5 | 100 | 124 | 135 | 118 |

| 6 | 10 | 136 | 148 | 131 |

| 6 | 100 | 143 | 152 | 134 |

NOTE: The Lower Lbs./Sq.In. Required to stop the flywheel, the higher the frictional properties.

Results: Pressure required to stop the flywheel on "ALTO RED EAGLE" are slightly lower than "Manufacturer A" and well below "Manufacturer B."

Conclusion: The frictional properties of "ALTO RED EAGLE" are slightly higher than "Manufacturer A" and well above "Manufacturer B."

| LEVELS | INERTIA (lb.-ft.2) | KINETIC ENERGY (lb.-ft.) |

| 1 | .261 | 30,232 |

| 2 | .302 | 35,048 |

| 3 | .344 | 39,865 |

| 4 | .385 | 44,681 |

| 5 | .426 | 49,498 |

| 6 | .510 | 59,131 |

Test Schedule and Duration:

Test conducted in six energy levels. Each level consists of 100 clutch engagements at 60 second intervals, from 4600 RPM with a clutch lockup time of one second, the indicated pressure required to stop the flywheel in one second.

Details

- SC-4L80E-CAT5-A

- SC-4L80E-CAT5-A

- SC-4L80E-CAT5-A

- SunCoast Performance

- New

Categories

Shipping Information

- Item Requires Shipping

- 85.0 lbs.

- W24.0000” x H24.0000” x L12.0000”

- Free Shipping!

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

Powered by Web Shop Manager.

WARNING: Cancer and Reproductive Harm

Write the First Review!