FREE SHIPPING ON ORDERS OVER $500

PLUS ADDITIONAL 5% OFF!

Use Code: BUILTWITHLOVE

Excludes Coan, ATI, and Reid Products. Limited Time Only. Shipping Discount automatically applied at checkout.

*One-way shipping only. Not valid for AK or HI.

Use Code: BUILTWITHLOVE

Excludes Coan, ATI, and Reid Products. Limited Time Only. Shipping Discount automatically applied at checkout.

*One-way shipping only. Not valid for AK or HI.

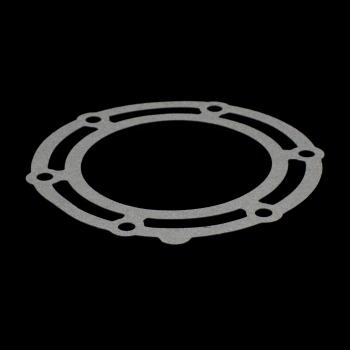

ZERO BALANCE FLEXPLATE

This replaces the factory flywheel/flex plate with a improved billet steel one-piece design and eliminates the heavy cast iron and the weak stamped steel flex plate. This is a must with the high torque in conjunction with a better designed torque converter that can transfer the torque with no slip.

The flex plate is bolted to the crankshaft and then the converter is bolted to flex plate. The torque from the motor is transferred to the flex plate, then goes from the flex plate to the torque converter and finally to the in- put shaft in the transmission. With increased torque from the engine, it can crack and/or rip the center out of a stock flex plate.

NOTE: A SFI certified flywheel flex plate is re- quired on drag racing vehicles running 11.99 and quicker in the 1/4 mile and 7.49 and quicker in the 1/8 mile, or any vehicle exceeding 135 mph. It was changed in 2008 from the 29.1 SFI specification to the SFI specification 29.3 for automatic transmission flex plates for diesel applications. The new rules for the flex plate requires that the material cannot be a stamped metal as are many OEM and after market flex plates. To maintain the SFI specification 29.3 requirements, the flex plate must be replaced every three years.

You must login to post a review.

Write the First Review!